Processes

Yeuell Nameplate & Label creates rugged and durable labels, engraved nameplates, tags, and panel fronts using various materials and modern technologies. Our offerings now include QR codes and polyurethane domed labels alongside classic work such as etched and anodized aluminum nameplates, meeting modern labeling, and ID needs.

Etching

Yeuell produces etched nameplates by applying an acid-resistant coating to metal sheets with a printed image. The sheets are then submerged in an acid bath, which removes exposed metal areas. Once enough material is etched away, the sheets are removed, rinsed, dried, painted with enamel, and baked. After baking, the sheets are cleaned to remove the initial coating, then clear-coated, lacquered, and baked for added protection and durability, making them suitable for indoor and outdoor use.

Screen Printing

Screen printed Yeuell nameplates are similar to lithographed nameplates, involving the direct application of ink on top of the material or on the bottom for transparent plastics. A polyester screen with a stencil is used to push ink onto the nameplate material using a squeegee. The nameplates are clear-coat lacquered and baked for beauty and durability. Screen printed nameplates use hard, light-fast inks, making them suitable for indoor and outdoor use. They are costlier than lithographed nameplates but more affordable and less durable than etched Yeuell nameplates.

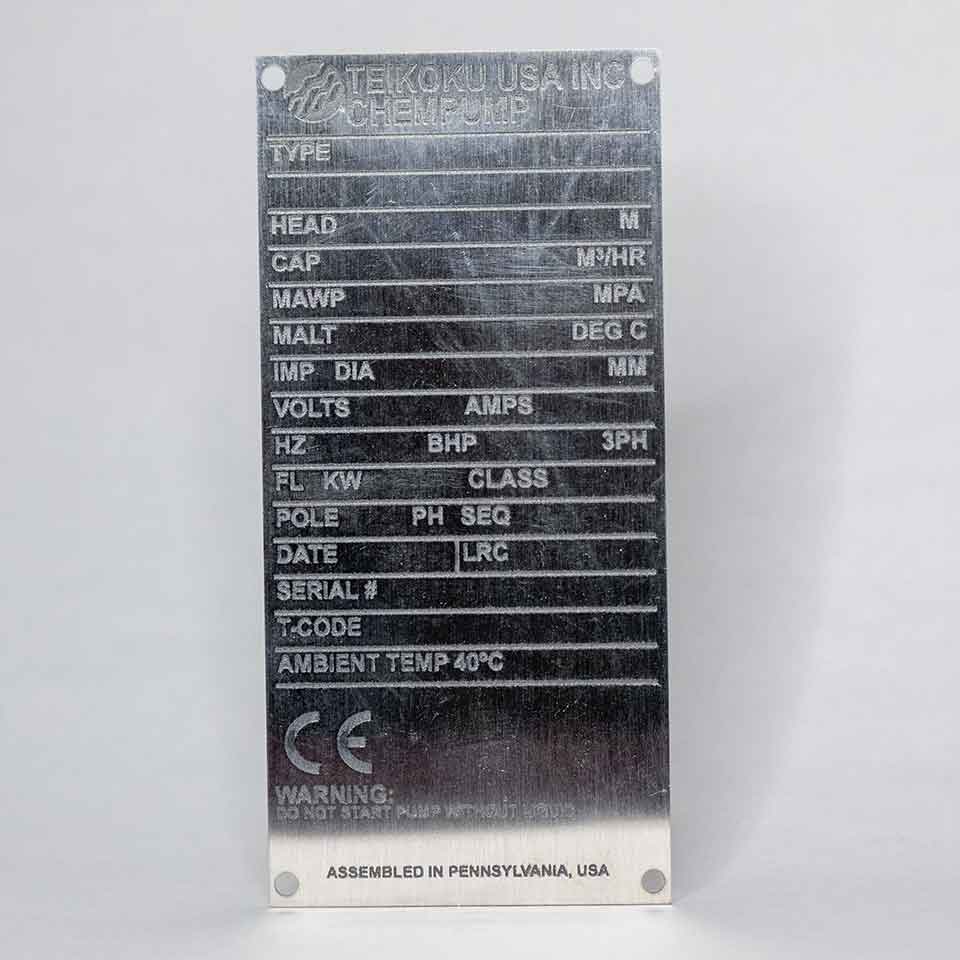

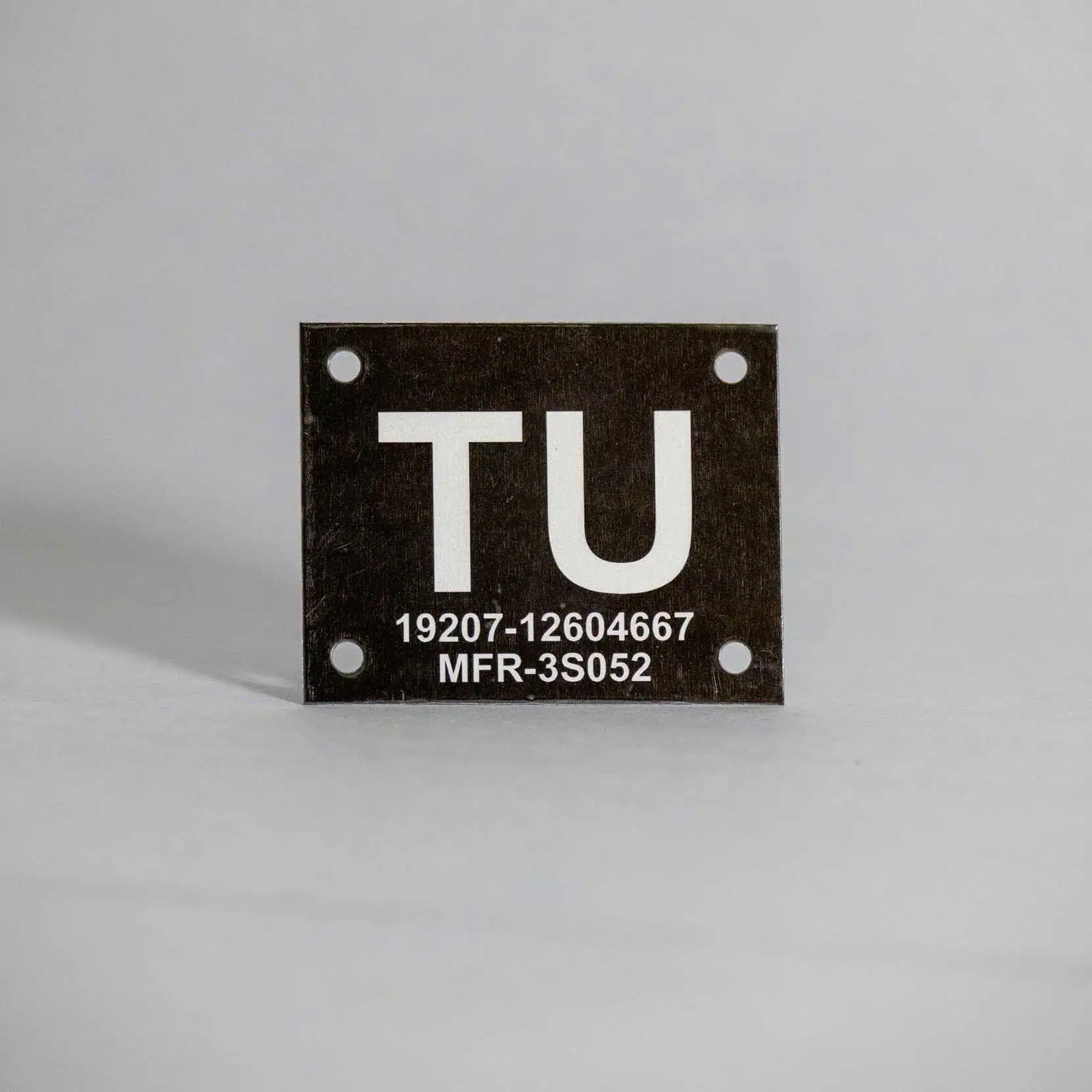

Mechanical & Laser Engraving

Mechanical engraving at Yeuell uses a high-speed rotary cutting tool to carve into metal or plastic surfaces, followed by filling the engraved area with enamel paint. This electronic process can engrave artwork files, including logos and special characters, onto nameplates made of brass, aluminum, or other materials. Yeuell also uses laser engraving with a CNC driver for precise and quick engraving down to .005 inches, ideal for fine detail on plastic and permanently marking stainless steel with ceramic-fired black copy. Both methods are consistently used for nameplates, tags, and custom ID projects for various customers, including municipal and industrial sectors.

CNC/Laser Cutting

Yeuell uses advanced CNC cutting machines, including CNC punching, lasers, and milling machines, which eliminates costly tooling needs. Custom shapes, tight tolerances, and fast lead times are straightforward for Yeuell. CAD files can be directly downloaded to CNC cutters for precise and perfect fitting.

Lithography

The lithograph process is an offset printing method where a master image is applied to a metal printing plate mounted on a specialized flat-bed press. A moving carriage with inking rollers and a rubber cylinder (blanket) transfers the image from the plate to the blanket, then onto the nameplate. This process uses minimal ink, allowing for extremely fine detail in direct and reverse print. However, lithographed nameplates do not hold up well in outdoor or harsh environments.

Photo Anodizing

In the photo anodizing process, an image is exposed onto specially coated aluminum and developed like photographic film. The aluminum is then sealed, trapping the image under an anodized layer, resulting in a hard, chemical- and heat-resistant nameplate. Photo anodized nameplates and labels need no additional lacquer for protection. This process uses a photographic film master, eliminating the need for plates or screens. It’s ideal for small quantities of highly durable nameplates with a quick turnaround.

Finishing

Yeuell offers a comprehensive range of decorative and protective finishing applications for custom ID needs. Options include gloss, clear, and matte lacquer finishes, as well as polyester, polypropylene, and polycarbonate over-laminates. Specialty finishes such as urethane doming and surfaces compatible with ball-point pen or typewriter markings are also available.

Digital Printing

Our digital printing process is designed to deliver high-quality, precise, and efficient printing solutions for nameplates, labels, and other industrial-grade applications. Utilizing state-of-the-art digital printing technology, Yeuell provides unparalleled flexibility and speed, allowing for quick adjustments in color, design, and materials without the need for traditional printing plates. Whether it’s for branding, identification, or compliance, Yeuell’s digital printing offers sharp, resilient, and customizable results tailored to our client’s exact specifications.